Burning is the final operation in the process of brickmaking. Green bricks are burned inside the kiln, which is a large oven used for the burning of bricks. The kiln converts the loose clay into a hard and stable end product. The burning process determines the properties of the bricks, such as strength, porosity, stability against moisture, hardness, etc. Bricks are burned at about 1000-1200 degrees Celsius. They are not burned above this temperature because it affects the shape and workability of the brick.

Types of Kilns

A variety of kilns have been invented over the years with varying degrees of efficiency and cost. There are two main types of brick kilns, based on the production process and the flow of air in the kilns. The two basic types are:

- Intermittent Kilns

- Continuous Kilns

Intermittent Kilns

In intermittent kilns, bricks are fired in batches. After each batch has been fired, the fire is allowed to die out, and the bricks are allowed to cool. The kiln is emptied, refilled, and a new fire must be started for each batch of bricks.

Intermittent kilns are still widely used in several countries in Asia, Africa, and Latin America. Since only one process can take place at a time, they are also called periodic kilns. These kilns may be rectangular or circular in shape, depending on local convenience, and can be either underground or above ground.

Intermittent kilns are subdivided into two categories based on the direction of airflow with respect to the brick setting in the kiln. They are:

- Intermittent Updraught Kiln

- Intermittent Downdraught Kiln

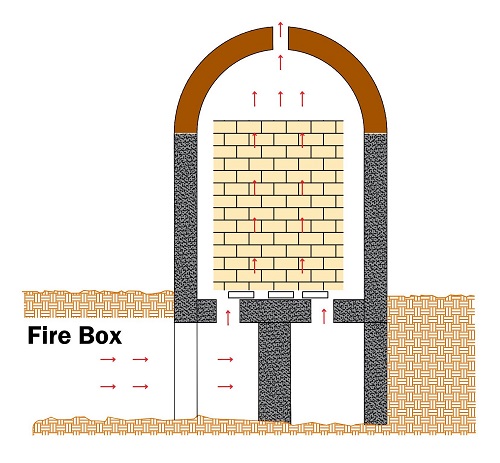

Intermittent Up-draught Kiln

Updraft kilns are those in which the flame is introduced into the bottom of the kiln, at or below floor level, and the exhaust gases are released from the top. The roof of the kiln is typically covered with inexpensive and lightweight materials to protect it from rain. Once the flues are ignited, the roof covering is removed to allow the fire and smoke to escape. Doors are provided on both sides for the loading and unloading of the bricks.

Working of the Intermittent Updraft Kiln

The raw bricks are arranged in rows, with a thickness of 2-3 bricks and a height of 6-8 bricks. A gap of 2 bricks is left between each row to place the fuel. The doors at both ends of the kiln are sealed with dry bricks and a layer of mud to prevent air leakage.

Once the setup is complete, the kiln is fired. A slow fire is maintained for the first 3 days to dry up the organic matter and moisture in the bricks. Rapid firing follows, as strong fire is applied for 4-5 days. The rate of firing is very important, as it directly impacts the final properties of the bricks. In this system, hot gases rise upward from the bottom while the bricks are burning.

After the firing is completed, the bricks are allowed to cool down, and then they are removed from the kiln. This process is repeated for the next batch of bricks.

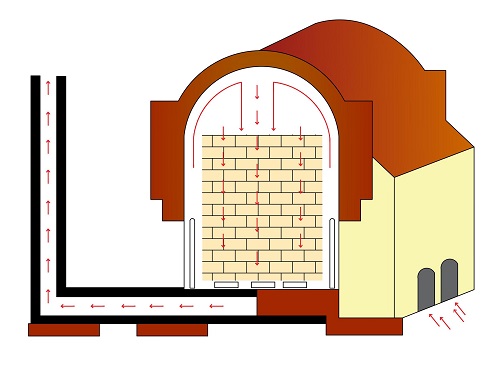

Downdraught Kiln

The downdraught kiln is an intermittent kiln in which the bricks are fired in batches. In this kiln, the hot gases from the burning fuel are first deflected to the roof of the kiln and then drawn downwards by the chimney draught through the green bricks to fire them. These kilns have permanent walls and airtight doors. They are also equipped with a permanent roof and a central chimney.

One of the advantages of this kiln is that the fuel and fuel residue do not come into contact with the kiln charge, which means no pollutants are deposited on the surface of the bricks or products.

The working process is similar to that of the updraught kiln.

Continuous Kilns

These kilns operate continuously, meaning that loading, firing, cooling, and unloading occur simultaneously. In a continuous kiln, the fire is always burning, and bricks are being warmed, fired, and cooled at different parts of the kiln at the same time. Fired bricks are continuously removed and replaced by green bricks in another part of the kiln, which is then heated. The rate of input and output remains constant.

The heat in the flue gases is utilized for heating and drying the green bricks, while the heat in the fired bricks is used to preheat the air for combustion. Due to the incorporation of heat recovery features, continuous kilns are more energy-efficient.

Continuous kilns are used when there is a high demand for bricks in a short amount of time. The brick burning process is completed in one day, making it a fast and efficient method of burning.

This kiln further classified into three types based on their performance.

- Bull trench’s kiln

- Hoffman’s kiln

- Tunnel kiln

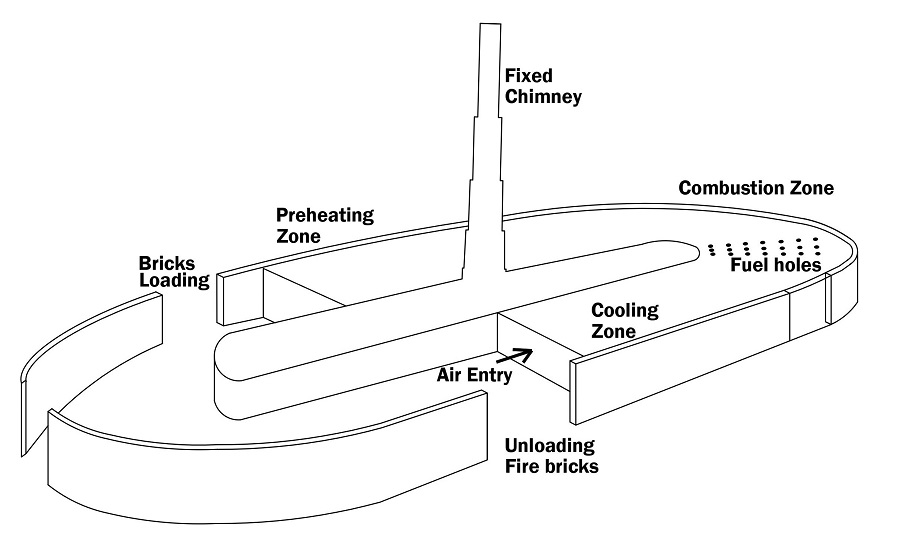

Bull Trench Kiln

The Bull’s Trench Kiln is one of the most commonly used types of brick kilns in South and Southeast Asia, accounting for more than 70% of total brick production in India. It is a continuous, moving fire kiln in which the fire is always burning and moving forward in the direction of the air flow, driven by the draught created by a chimney. The bricks are warmed, fired, and cooled simultaneously in different parts of the kiln.

This kiln is a modified version of the original Bull’s Trench Kiln, introduced by the British engineer W. Bull in 1876. Initially, the kiln had movable metal chimneys placed over the brick setting, which were moved as the firing progressed. Over time, this technology evolved into the more efficient and less polluting fixed chimney version, known as the Fixed Chimney Bull’s Trench Kiln (FCBTK). A large-scale shift occurred toward FCBTKs following regulatory bans on the use of moving chimney kilns in the 1990s.

The Bull’s Trench Kiln (BTK) can be circular or rectangular in shape, with the chimney located in the centre. The kiln is divided into three distinct zones:

- Preheating Zone: In this zone, green bricks are stacked and preheated by the flue gases.

- Combustion Zone/Firing Zone: This is where the fuel is fed, and combustion takes place.

- Cooling Zone: Fired bricks are cooled by cold air entering the kiln.

Raw bricks are placed between the inner and outer walls of the kiln with even spacing between them. The fire rotates around the kiln while the bricks remain in place. The movement of fire in the kiln happens in the direction of air flow.

The kiln does not have a permanent roof, so the bricks stacked inside are covered with a layer of ash and brick dust. This acts as a temporary roof, which helps reduce heat loss and prevents leaks. However, the kiln can face challenges during the monsoon season.

Working of the Bull’s Trench Kiln

- Cooling Zone: Fired bricks are placed in this zone. As air enters from the unloading end, it absorbs heat from the fired bricks, thus heating the air while cooling the bricks.

- Combustion Zone: Fuel is fed into this zone through feed holes on the roof of the kiln. Typically, 3-6 rows of fuel are added continuously. Fuel is fed at intervals of 15-20 minutes, with each feeding lasting 5-10 minutes. Coal comes in contact with hot gases, and combustion occurs in this zone.

Once the fire is started, it continuously travels from one chamber to another, while other operations—such as loading, unloading, cooling, burning, and preheating—take place simultaneously.

The hot air moves from the combustion zone to the preheating zone, where green bricks are kept. After passing through the flue chamber, the hot air exits through the chimney. The kiln operates under a natural draft, provided by the chimney, in a continuous cross-draft and annular moving fire system.

Every day, fired bricks are unloaded from the front of the cooling zone, and an equivalent batch of green bricks is loaded into the preheating zone. The operation does not require electricity, making it an energy-efficient and cost-effective option for large-scale brick production.

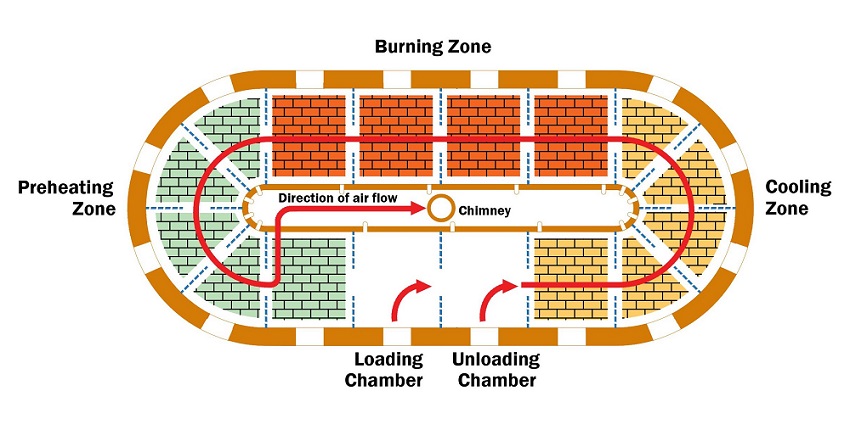

Hoffman’s Kiln

The Hoffman kiln is a continuous, moving fire kiln that operates 24 hours a day, throughout the year, except during maintenance. In this kiln, the fire burns and moves forward through the bricks stacked in the kiln. The movement of the fire is caused by the draught provided by a chimney or a fan. It is also called a ring oven or ring kiln.

The burning takes place at a temperature of around 1,000°C. The kiln has a circular, elliptical, or rectangular brickwork structure consisting of an endless tunnel, divided into 12 to 24 chambers, all interconnected to each other and to a main flue leading to a large chimney.

The Hoffman kiln was invented by Friedrich Hoffman in Germany in 1858. These kilns were once widely used in Europe for brick, ceramics, and lime production. The Hoffman kiln technology was introduced in India by German missionaries in the 19th century. The original design of the Hoffman kiln had a circular circuit built around a central chimney. However, this design has been modified over time, and now Hoffman kilns with elliptical or rectangular shapes are more commonly used.

The Hoffman kiln has a permanent roof, so it can be used to manufacture bricks even during the monsoon season. Each of the chambers has an opening for loading and unloading the bricks, which is closed by a door or a temporary brick wall. At the top of each chamber’s arches, there are several small feed holes through which fine coal can be fed into the spaces between the bricks to be fired.

Working of the Hoffman’s Kiln

There are three distinct zones in an operating Hoffman kiln:

- Burning Zone: Where the fuel is fed, and combustion occurs.

- Brick Preheating Zone: Located in front of the burning zone, where green bricks are stacked and preheated by the flue gases.

- Brick Cooling Zone: Located behind the burning zone, where fired bricks are cooled by cold air flowing into the kiln.

If the chambers are numbered from 1 to 12, bricks are loaded into chamber 1 and unloaded from chamber 2. When the kiln is in full operation, the loading and unloading chambers will be open, and the other ten chambers will be closed. The damper is closed between chamber 1 and chamber 12 but opens between all other chambers.

Air enters the kiln through open doors 1 and 2. Burnt bricks are kept in chambers 3, 4, 5, and 6. The cold air entering the kiln will pass through these hot bricks, cooling them while the air heats up. The firing of bricks takes place in chambers 7 and 8. Fuel is fed through the fuel holes provided in the roof at intervals of every 15-20 minutes, with each fuel feeding lasting 5-10 minutes. The hot air passes through the bricks in chambers 9, 10, 11, and 12, preheating them.

Commonly used fuels are biomass (mainly firewood) and coal. Between 10,000 and 20,000 bricks can be produced in one day. Daily, fired red bricks are unloaded from the back end (chamber 2) of the brick cooling zone, and an equivalent batch of green bricks is loaded ahead (chamber 1) of the brick preheating zone.

Both the Hoffman kiln and the Fixed Chimney Bull’s Trench Kiln (FCBTK) are suitable for firing all types of products. However, the quality of bricks fired in a Hoffman kiln is superior. Since the Hoffman kiln has a permanent roof, the initial cost is almost double that of the FCBTK, but the bricks produced are of superior quality.

Tunnel Kiln

The tunnel kiln is the most advanced brick burning technology. It was invented in 1877 in Germany. Although it was developed in the 19th century, its application took place in the 20th century.

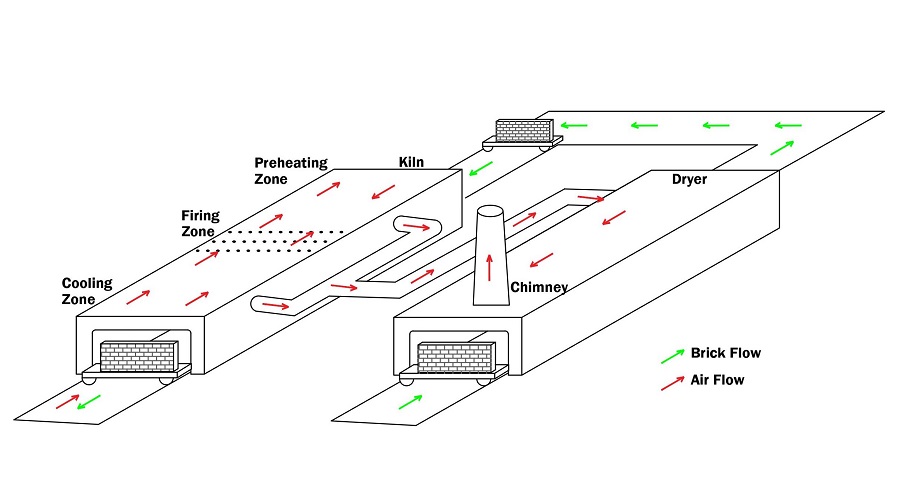

In a tunnel kiln, bricks are stacked on a heat-resistant trolley or kiln car and pass through a long horizontal tunnel. The firing of bricks occurs in the central part of the tunnel. From the cool entrance, the temperature is steadily increased as it approaches the central, hottest part of the kiln. From there, it continues through the tunnel, and the surrounding temperature is reduced until it exits the kiln nearly at room temperature.The length of the tunnel can vary from 60m to 150m.

Initially, green bricks are sent by wheeled cars into a chamber for drying. The hot flue gases generated in the kiln during the firing process are used for this. This chamber is called the dryer.

After drying, the cars are pushed through the tunnel into the firing zone. The cars move inside the tunnel intermittently at fixed time intervals. The duration of the firing cycle can range from 30 to 72 hours.

The firing zone has three segments:

- Firing Zone: The combustion zone where granular fuels are fed from the top of the tunnel. The temperature in this zone should be maintained between 900°C and 1050°C.

- Preheating Zone: Where the green bricks are preheated before being burned by the hot flue gases.

- Cooling Zone: Where the burnt bricks are cooled by the cold air flowing into the kiln.

Fuel is fed through the feed holes provided on the top of the kiln roof, located just above the firing zone. Granulated coal and petcock are the most commonly used fuels. The firing zone usually extends up to 8 cars.

A counter current heat flow is generated in the firing tunnel. The cold air enters the kiln from the exit end of the car, gets heated while cooling the fired bricks. These hot flue gases then move through a pipe to the drying chamber and are finally released into the atmosphere through a chimney.

The distribution of heat is uniform, which results in a high percentage of good-quality bricks (95%).